If you have spent the effort and time researching a heat exchanger for your question, you have probably come across various advice from companies. So what’s the difference between them, and most importantly, which one do you need to get the job done?

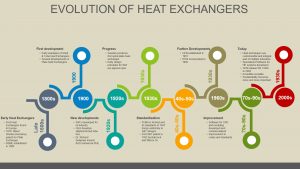

The heat exchanger is born

A little background might be helpful. Plate heat exchangers appeared in the 1920s and were used in the food industry. After Louis Pasteur introduced the term ‘pasteurisation’ (killing bacteria in milk by heat) at the end of the 19th century, plate heat exchangers appeared in the 1920s and were used in the food industry.

In the early 1930s, Sweden made the first spiral plate heat exchanger. Then the United Kingdom used a brazing method to make a plate-fin heat exchanger from copper and alloy materials for the heat dissipation of aircraft engines

In the late 1930s, Sweden produced the first plate heat exchanger for use in pulp mills. During this period, people began to pay attention to the heat exchanger, which were made of new materials to solve the heat transfer problem of highly corrosive media.

Industrial development

Around the 1960s, due to the rapid development of space technology and advanced science, the urgent need for a variety of high-efficiency compact heat exchangers came along, coupled with the development of stamping, brazing and sealing technology. As a result, the heat exchanger production process has been further improved, promoting the vigorous development and wide application of compact plate heat exchangers. In addition, since the 1960s, the typical tubular heat exchanger has been further developed to meet the needs of heat exchange and energy saving under high temperature and high pressure.

Software developments

Computer-Aided Design (CAD) software began developing in the late 1950s, with the general consensus that Ivan Sutherland’s “Sketchpad” was the first true CAD software. Sutherland developed Sketchpad in the early 1960s as part of his dissertation at MIT. Industries slowly began to move to using CAD software to mechanically design heat exchangers. Founded in 1962, HTRI was chartered to conduct application-oriented research in heat transfer and fluid flow technology. HTRI is today one of the most trusted research institutions in the world and their software has helped design various heat exchangers.

M&S Computing (Currently Hexagon PPM) was founded in 1969 in Alabama, USA. They developed the first interactive CAD product, Interactive Graphics Design Software (IGDS), which became an industry standard in a very short period of time. They went on to develop PV Elite, one of the most well-known mechanical design software today.

Thermal design and modeling had a slower start, with the first commercial use of computer software in the 1970s. While research remained a top priority, in the 1990s it became clear to multiple industries that using computers to design, model and simulate was the norm.

Development in code and standards

TEMA was founded in 1939 as an association of Shell & Tube heat exchanger manufacturers to bring uniformity to designs, and ‘The TEMA Standards’ is still considered the standard to be followed for Shell & Tube heat exchanger design in the industry.

The American Society of Mechanical Engineers or ASME was founded in 1880. ASME has codes and standards for various fields of engineering and components. ASME has more than 110,000 members in more than 150 countries worldwide. The main purpose was to prevent the failure of boiler pressure vessels. The ASME VIII code refers to the pressurized parts of a shell & tube heat exchanger, which covers the parts in the shell, mainly the tubes. Sections II and V, which refer to materials and non-destructive testing, are also occasionally used for design purposes.

The CEN (French for Comité Européen de Normalisation), also known as the European Committee for Standardization, is a public standardization group established in 1961. The 34 Member States work together to develop European Standards (ENs) in different sectors/services and are officially recognized as a European standardization body by the European Union, the European Free Trade Association and the United Kingdom. EN 13445, a relatively new code for pressure vessels, came into full effect on May 22, 2002. Written with the European Pressure Equipment Directive, it was compiled by CEN Technical Committee TC54 for 10 years. While it lacks a strong historical background and suffers from the disadvantage of lowest common denominator writing, it was written by experts responsible for maintaining the various national codes and is intended to be updated regularly to fill existing gaps.

Sustainability arrives

The environmental issue, already discussed in the Netherlands during a Christmas speech by Queen Beatrix in 1988, becomes more active in the 1920s. More demands are being made on everything that has to do with heating and cooling, both at home and in an industrial environment. The call for ‘the polluter pays’ is getting clearer and clearer!

The ‘traps’ of solutions

So now that the terms are defined, one question…why continue to offer the easiest or most (for the seller) profitable solutions instead of a custom, specialized solution that can meet all needs? Do we really need the cheapest solution ‘at the moment’, or are we better served with a solution that provides insight into the purchase, maintenance, operational costs and lifespan?

Salespeople looking to score “easy” can give you serious headaches and growing pains. If the capacity of your heat exchanger is limited, the heat exchanger quickly becomes dirty, you are not told what the maintenance instructions are, you do not have insight into what the various replacement parts cost, ouch! When the heat exchanger falls out of service, the costs can be enormous!

The philosoply of Spiralex

One heat exchanger advice that works wherever you need it sounds simple, but realistically it’s extremely difficult to get it right. Remember that it should be simple enough for a quick advice, but there is always more to a heat exchanger: namely an entire process! Even with the most ‘simple’ request, you are dealing with the process behind it and the future: are we going to expand, what is the lifespan, what are the future costs, etc. The technology is only the first part; the (future) costs and lifespan must be transparent to everyone.