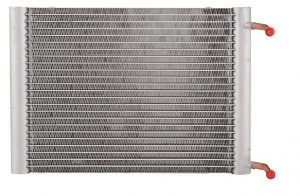

Microchannel heat exchangers (MCHE) are a variation of fin and tube heat exchangers. At least one liquid, usually refrigerant or water, flows through tubes or closed channels, while air flows cross-flow through the connected fins. The hydraulic diameter of the channels is less than 1 mm.

Microchannel heat exchangers (MCHE) are a variation of fin and tube heat exchangers. At least one liquid, usually refrigerant or water, flows through tubes or closed channels, while air flows cross-flow through the connected fins. The hydraulic diameter of the channels is less than 1 mm.

The transportation and chemical processing industries have been using MCHEs for decades. The pursuit of improved efficiency led to the use of MCHEs in HVAC systems. In order to be used in HVAC systems, different requirements have been placed on the MCHEs, which have been recently improved and developed.

The manufacturers initially focused on aluminum materials and solder constructions. The use of a single material ensures consistent heat transfer. The high temperatures used in the brazing process create a strong metallurgical bond. These methods increase heat transfer.

Other design changes include, for example, condensation and corrosion limitation and improving the flow of the fluid. The size and number of the headers and the orientation of the microchannels can vary depending on where the heat exchanger is located in the HVAC system and the fluids to be used. Some MCHEs are specifically designed to accommodate the phase changes (vapour-liquid) in condensers and evaporators.

Advantages

Are they perfect? No!

Two disadvantages are worth mentioning. Condensate can interfere with efficiency by blocking airflow through the fins. Another problem is the distribution of the refrigerant flow. Design features to address these issues include channel orientation, fin design and spacing, and baffles or holes in headers to control flow.

With the efficiency benefits, the use of MCHEs in HVAC will increase. The cost of raw materials for production and the cost of refrigerants will be lower than traditional exchangers. Copper, which is used in traditional fin and tube heat exchangers, is more expensive than aluminum. Additional savings from reduced refrigerant build-up encourages companies to choose MCHEs over traditional heat exchangers for their HVAC needs.

Compared to other industries, the market for MCHE in HVAC is relatively new. Manufacturers have redesigned these heat exchangers to maximize heat transfer properties, reduce unit manufacturing and operating costs, and reduce the space required for HVAC systems.