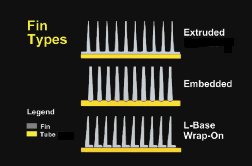

Fins in an air coil are attached to the tubes in a number of ways:

- through an extrusion process where the aluminum fins are extruded and integrally bonded to the full length tubing.

- by spirally wrapping a strip of aluminum around a tube, it closes in a pre-cut spiral groove to secure the fin.

- by winding on an aluminum strip standing on a foot, which is wound on the tube as a base.

The figure to the right shows an exploded view of the above-mentioned fin structures.

Sometimes serrations are cut into the fins. This causes an interruption of the air boundary layer, generating an increase in turbulence, which in turn increases the heat transfer coefficient on the air side, with a modest increase in air side pressure drop and fan power.

Choise

The choice of fin types is critical. This choice is influenced by cost, operating temperatures and atmospheric conditions. Each type has different heat transfer and pressure drop characteristics. The extruded tube offers the best protection of the tube against atmospheric corrosion. The heat transfer is highest in this case due to the large contact surface between tube and fin.

The fin tube with wrapped base is mechanically the least strong; the fin and tube can become detached from each other over time. The heat transfer is therefore a lot less.