Very powerful and compact range of coiled heat exchangers with tubes made of acid-resistant stainless steel or copper tubes. These heat exchangers are suitable for many different media, such as steam, domestic hot water, heating water and thermal oil.

The corrugated tubular heat exchangers, CTHE for short, are made entirely of stainless steel and consist of a bundle of corrugated tubes mounted in a corrugated or smooth outer tube (shell). Due to the corrugated inner tubes (“corrugation”), the turbulence of the liquid will increase. The high turbulence also ensures that the exchanger has a self-cleaning effect and needs less heat transfer area.

The P-line tubular heat exchangers are specially designed for the pharmaceutical industry. They are also suitable for other FDA and 3A compliant applications. The unique construction (double tubesheet) prevents contamination of media, even in the event of a leak in the tube sheet – tube connection. Thanks to the low roughness of the pipes and the arrangement of the connections, the exchanger can be completely emptied by gravity alone. High-quality materials ensure safe and long-lasting operation/service life of the heat exchanger.

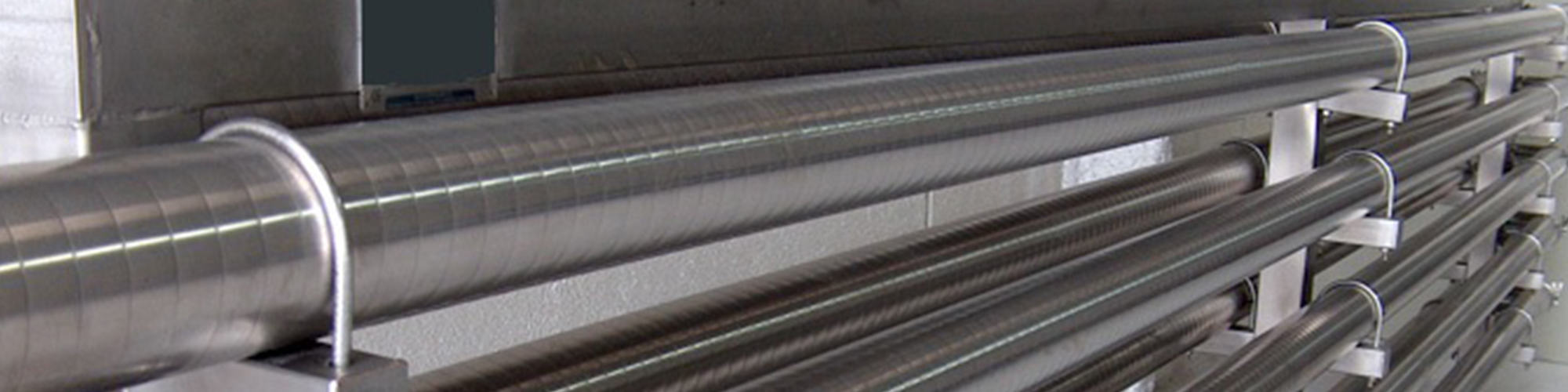

A U-tube heat exchanger (also called a “hairpin”) is a thermally efficient tube heat exchanger, resulting in lower costs, more compact construction and lower weight. A U-tube heat exchanger can be demountable, but the inner tubes are not easy to inspect. If there is contamination or particles in the flow, this can lead to blockage.

The TEMA heat exchanger is a tubular heat exchanger, which is made of steel, stainless steel, titanium and other more exotic materials. TEMA stands for Tubular Exchanger Manufactures Association. TEMA is a set of standards developed by leading heat exchanger manufacturers. These manufacturers have defined the heat exchanger style, the machining and mounting tolerances to be used in the fabrication of a particular exchanger.